Affinity Design process

We pride ourselves on our ability to offer a unique and highly recommended bespoke shaped wedding ring service. Our process allows you to get a fitted/shaped ring without the need to art with your engagement ring. Even better still, we can get your design created and images sent to you within a week. Below I will talk about the steps involved in the bespoke shaped service.

- There are 2 ways to start the process. The first is by visiting our store. You will be greeted by a member of staff who will talk to you about the type of ring you are looking for, they may draft a rough drawing or help you find aspects of rings you like. They will pop your engagement ring into one of our moulding putty and you will be charged your design fee in store. You will walk away with your engagement ring, no need to leave it with us.

Secondly, you can head to our website and order one of our mould kits, it will usually arrive in 1-2 days. In your pack you will receive a pot of 2 different coloured putties, instructions on how to do your mould, a form for you to write about the type of design you would like and also a return addressed envelope. - Once your mould has been completed and we have received it into the store, we will fill this with a liquid that hardens, giving us a replica of your engagement ring. We will then scan this and create a 3d file for our design team to use and create your design around.

- Within 1 week you will receive your design images, pricing and details of your design. If you have ordered your kit online, it is at this point that you will be charged a one off design fee and this will be deducted from any costing should you go ahead and purchase. If you are happy you can request a resin version of your design to try on for size and fit or alternatively, if there are any tweeks you would like to make, this can be done for you no problem.

Alterations will usually take a couple of days. - When you are happy with your design, you can request a resin version of your design. This is a plastic type material of your design and enables you to effectively ‘try before you buy’. It gives you confidence in being able to see your design on your finger and see how it fits with your engagement ring. Your first resin is FREE and should you require any more they will be an additional cost of £5.

- Once you are 100% satisfied with your design then you can proceed. Payment in full is required at the time of ordering and we have a few different ways you can pay. Once payment is received we have an approximate lead time of up to 21 working days.

How long does the process take?

We advise you to leave an absolute minimum of 8 weeks from the time of ordering your kit to the time you receive your ring. This will allow for any holdups along the way and any alterations if needed. However, your ring has to be perfect for you, after all it should last a lifetime and the longer you can give the process, the better.

Why am I charged a design fee?

Let me explain, in brief, the process.:

- Once we receive your mould into the store, we check it in and mark it as received which will then automatically send you an email.

- We will then fill your mould with a liquid that hardens overnight.

- The next day we will pop your mould out and file it to shape.

- The next step is to scan this replica of your engagement ring so we have a 3d file.

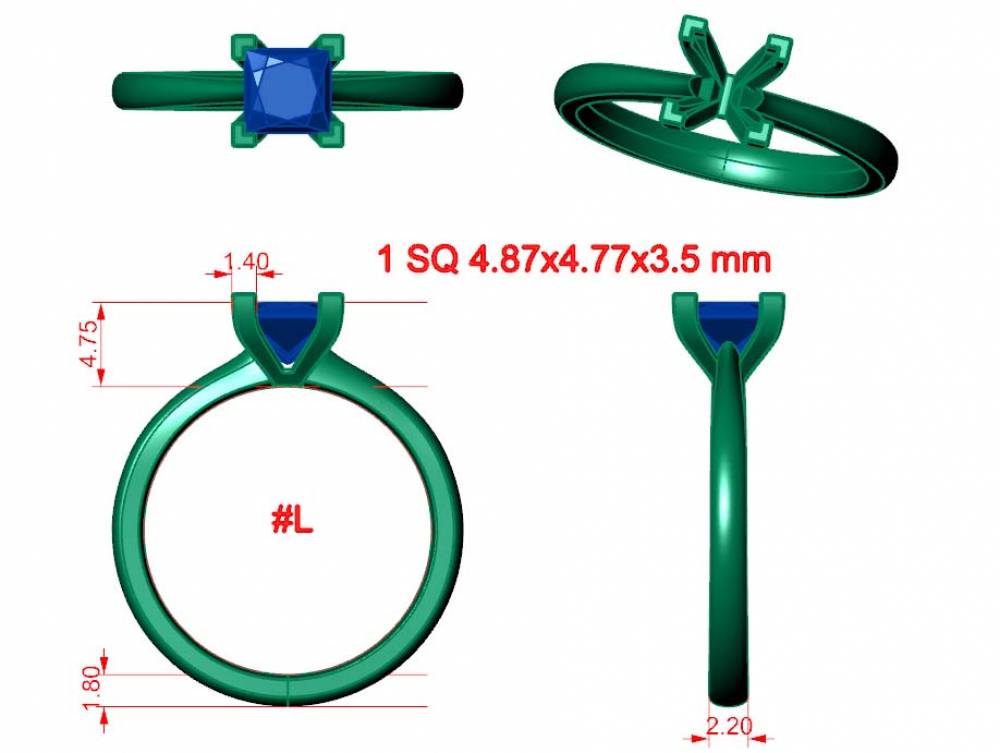

- The design team will then check over your form and any requirements you have. We measure all diameters and thickness of your replica ring to ensure it is as close a match as it possibly can be to your actual ring.

- The team will then work on creating your design over a few days.

- Once all images are complete we will then price your design based on the metal weight, any stone contents or other requirements such as hand engraving etc.

I hope from reading the above, it helps you to understand how much time, skill and expertise goes into each and every design and this is without any possible time spent altering designs. We consider our design fees to be very reasonable and affordable to most, not to mention highly competitive within the industry.

Why is the cost of my design more than purchasing a traditional band?

So your design has been sent through, you wanted a plain shaped band and it has come in higher than a traditional band you may have seen on our website or any other website selling traditional bands for that matter, but why?

This is a question that every now and again will crop up. With a traditional band, you select the weight of the ring, the profile and width. The vast majority of these bands will be cut from a metal tube and then polished/finished to your liking. The weights and widths are standard and are pretty much purchased ‘off of the shelf’ if you like.

With a bespoke ring, you are getting exactly what you need/want. The profile, width and wall thickness will all be matched to your engagement ring. The price difference between the traditional and bespoke ring will all be down to metal weight. You see where we are matching your engagement ring, it won't be a standard ‘light, medium or heavy weight’ therefore there will be more metal involved. If the shape extends around the head of your current ring, or dips in to fit snuggly with your ring, this all requires more metal.

We fully understand that cost and budget plays a huge factor in your decision, this is why we offer all types of wedding bands. No one ring is more superior than another, be it bespoke or traditional style. I hope this has helped you to understand the differences in costing and remember that your wedding ring should last a lifetime. It is the most important part of your big day, it is the one thing that symbolises your marriage and requires thought.